In challenging economic times Knowlestry can give you the right impulse.

Knowlestry combines advanced AI capabilities with deep domain expertise to tackle industry-specific challenges.

Start your projectWhere to use Knowlestry

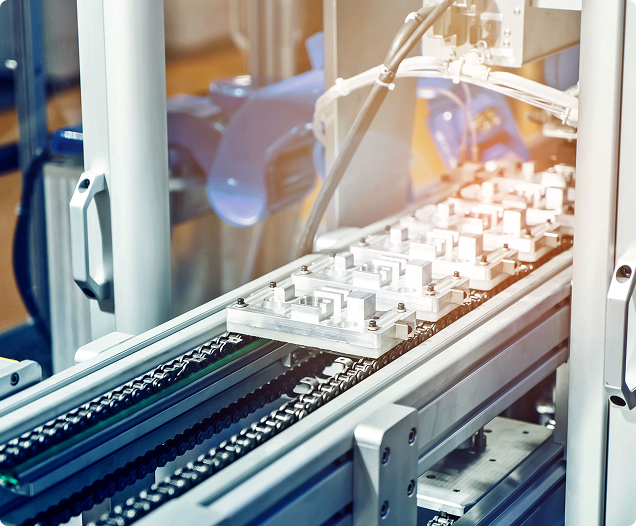

Automation of Machine Data Analysis

After-Sales Support and Technical Troubleshooting

Training and Onboarding to improve Employee Productivity

Operational Efficiency and Rapid-Cycle Innovation

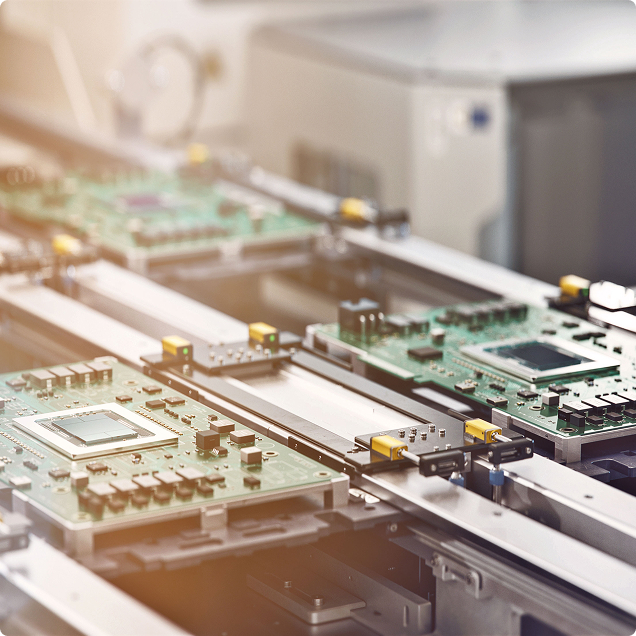

Detecting downtimes in EMS using generative AI and machine learning

Automation of Machine Data Analysis

Avoids catastrophic failures, lowers replacement costs, builds a culture of continuous improvement.

Knowlestry automates the analysis of machine data, helping you unlock real-time insights that drive faster decision-making and reduce operational costs.

Benefits

- Cost Savings: Shorten today's lengthy and expensive AI/ML development;

- Systematization: Integrate context into AI/ML development, bridging the gap between data analysts and domain experts;

- Transfer Performance: Benefit from sharing data analysis lessons-learned across your organization;

After-Sales Support and Technical Troubleshooting

Lower risk of recalls, sustained product quality, and consumer trust.

From the moment your machinery arrives at the customer site, Knowlestry provides a shared repository of product documentation, troubleshooting steps and real-time collaboration tools for service technicians and support staff.

Benefits

- Timely, accurate solutions lead to improved customer satisfaction and stronger brand loyalty;

- Fewer On-Site Visits: customers can troubleshoot common issues themselves, freeing your support staff for complex problems.

- Upsell and Cross-Sell Opportunities: Tracking usage data and common challenges allows you to proactively suggest complementary products or upgrades to your customers.

Training and Onboarding to improve Employee Productivity

A knowledge base that makes workers more effective and satisfied in their roles.

Knowlestry centralizes your critical manufacturing know-how, procedures, and best practices so new and existing employees can quickly learn and adapt.

Benefits

- Faster Onboarding: New hires get up to speed quickly with intuitive, step-by-step guides and on-demand tutorials.

- Consistent Knowledge Transfer: Veteran employees can easily capture their expertise, ensuring nothing is lost when people retire or change roles.

- Reduced Error Rates: With standardized instructions and real-time support, you significantly cut down on mistakes and rework.

Operational Efficiency and Rapid-Cycle Innovation

Consistent product quality, and accelerated time-to-market.

Using Knowlestry’s continuous feedback loop, you can refine processes, test new product improvements, and implement best practices across teams—faster than ever.

Benefits

- Streamlined Processes: Unify best practices company-wide, cutting down wasted time and miscommunication between departments;

- Accelerated Product Upgrades: Leverage data insights to evolve products rapidly based on real-world performance;

- Innovation at Lower Cost: By consolidating lessons learned, you avoid repeating mistakes, saving money and fostering a culture of continuous improvement;

Use Cases on Demand

Parameter optimization

Value:

Automatically determines the value of parameters to make machines and processes more efficient.

Example:

A rubber duck manufacturer wants to optimise production. This involves adjusting parameters like the melted material's temperature and injection pressure. This impacts defect frequency and efficiency. Currently, these are manually adjusted by experts.

Requirements:

- Interpretation of domain knowledge to determine relevant parameters and potential consequences of changed values.

- Modelling the relationship between parameter values and result quality.

- Optimise input parameter values based on the modelled relationship.

Solution:

Knowlestry facilitates the development of an AI model to describe the connection between configuration parameters and production error probability, and optimises inputs.

Impact:

This reduces the need for manual adjustment of these parameters and improves overall production efficiency.

Anomaly detection and classification

Value:

Automatically detects, classifies and explains irregularities in production or machine behavior, enabling quick responses if required.

Example:

A groundwater management service provider wants to automate the monitoring and reporting of changes in groundwater levels.

Requirements:

- Detection of events and changes in parameters like groundwater levels and water flows.

- Classifying events, identifying reasons, and finding connections between them.

- Evaluation and combination of data from different sources (databases, time series, individual measurements, natural language, event protocols)

- Prediction based on a large amount of previous data, which may be inconsistent.

Solution:

Knowlestry automates special event detection and classification with reporting.

Impact:

This reduces manual effort, saves money, reduces downtime and prevents breakdowns.

Condition Monitoring

Value:

Industry agnostic, real-time visibility into the health of components or machines.

Example:

A manufacturer of friction brakes provides digital services to its customers.

Requirements:

- State detection based on voltage and current;

- Handling of environmental influences such as: (A) supply voltage fluctuations (B) non-relevant AC components in the supply voltage;

- Balancing the risks of false positives and false negatives;

Solution:

Knowlestry developed an ML model that detects brake application/release via electrical voltage/current.

Impact:

Informs preventative maintenance plans, reducing unplanned equipment failures.

Quality Assurance

Value:

Automatically verifies whether produced parts or products meet defined quality standards, minimizing defects and ensuring compliance.

Example:

A manufacturer of precision metal parts wants to ensure product quality based on in-process measurements such as torque, force, temperature, and cycle times. Currently, deviations are only discovered during downstream inspections, which leads to costly rework and scrap.

Requirements:

- Collection and preprocessing of sensor and process data across multiple production steps.

- Learning correlations between machine data and known quality outcomes.

- Real-time or batch classification of parts into pass/fail categories based on predictive analytics.

Solution:

Knowlestry enables the development of a machine learning model that uses sensor and process data to detect patterns linked to quality deviations — identifying faulty parts before they move downstream.

Impact:

This enables early intervention in the production line, reduces downstream defects, and lowers costs related to manual inspections, scrap, and rework.